Verification of audit information is a key skill for carrying out an internal audit but the extent of verification, and techniques used, are often highly variable, and may have a significant impact on the validity of your audit findings.

Imagine that you are auditing a transport procedure for a company with a fleet of vehicles. The procedure requires that each vehicle is logged on a database including details such as service intervals, insurance details, and input of monthly mileage data. How would you sample this information and check that the overall process is working?

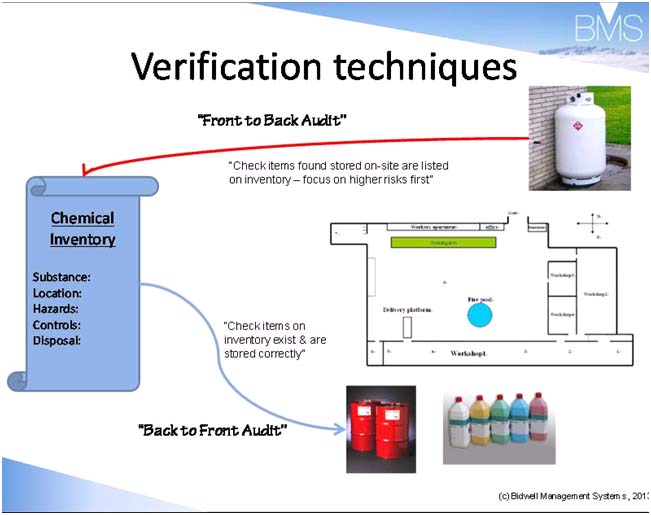

Observing hundreds of auditors in training I have noticed that many are comfortable discussing the process with the responsible person, taking a sample of information from a database, and then checking this information in a filing system. In this case they may also take sample mileage details from the database and check these against vehicle mileometers in the car park. I call this “back to front auditing”, or checking input data against reality. The auditee is normally relatively confident at this stage because we are checking what they know exists and have records for. In this example it is unlikely that a known vehicle will have missed its MOT or service, and any gaps in mileage data will show up clearly on the database.

In order to pressure-test the robustness of the process associated with identifying and recording new vehicles, decommissioning old vehicles, and regulating designated drivers the audit process should also be done the other way around or “front to back”. In this case it would involve walking around the depot recording a sample of number plates, or collecting this information from another source if all vehicles are on the road, such as sign-in logs, and then verifying that these vehicles exist on the database. At this point I often find that auditee becomes noticeably more alert and sometimes volunteers information in advance such as: “let’s hope the system’s working properly”, or “I’m not sure if the new vehicles have been put on the system yet because Kate’s been on holiday”, or even “this system only covers x and y type vehicles, but not z”.

This “back to front” and “front to back” audit technique can be applied to almost any environmental, health & safety, or quality audit and will improve your audit technique, lead to improvements in your organisations processes, and give your certification body confidence that you ISO 9001, ISO 14001, and OHSAS 18001 audit systems are sufficiently robust.

This technique is illustrated on the following diagram using a different example of a chemical inventory audit:

Next time you are doing an audit try to incorporate these techniques.

This article was written by Marek Bidwell of Bidwell Management Systems who provide a comprehensive ‘Internal Audit Service’ including on-site audit training for your audit teams, ongoing mentoring, and a full contracted out internal audit service.

You must be logged in to post a comment.